Alloy Steel Casting

Alloy steel castings refer to metal products that are manufactured by casting various alloy steel materials through different processes. Alloy steel castings are based on stainless steel castings, with additional materials added to the raw materials to meet the different mechanical properties required by parts.

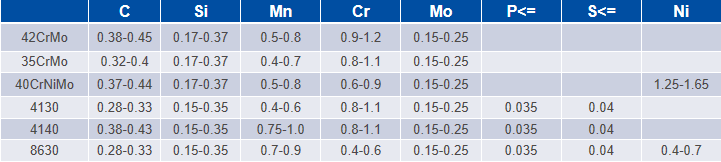

Compared to traditional metal castings made from single materials, alloy steel casting significantly enhances the performance of steel. Its strength, hardness, toughness, wear resistance, and other properties are improved. Alloy steel castings are widely used in many industries such as automotive, aerospace, energy, and more. The alloy steel material has special properties. The material structure of alloy steel is shown below.

Alloy Steel Casting Material

Alloy steel is made by adding one or more alloying elements, such as manganese, silicon, nickel, chromium, molybdenum, etc., to carbon steel. It can be categorized based on the content of alloying elements into low alloy steel, medium alloy steel, and high alloy steel; based on different applications, it can be divided into alloy structural steel, alloy tool steel, and special performance steel; according to the metallographic structure, it can be classified into pearlitic steel, bainitic steel, martensitic steel, and austenitic steel; and based on quality grade, it can be sorted into high-quality alloy steel and high-grade quality alloy steel.

Alloy steel investment casting samples

Alloy steel investment casting process

SHENGRONG strictly follows Standard Operating Procedures for each step of the alloy steel casting process. The main process flow of alloy steel casting is as follows:Pouring simulation、Mold development、Raw material inspection、Wax pattern making、Shell making、Metal pouring、Cleaning and heat treatment、Inspection、Warehousing, packaging, and transportation;

The technical department develops molds, while the quality department utilizes coordinate measuring machines for dimensional inspection.

An automatic waxing machine is utilized to set parameters such as waxing pressure and insulation time, producing high-quality patterns.

The workshop is equipped with automated production lines, capable of producing 1,500 sets of casings annually.

Operators conduct rigorous tests to meet material specifications.

The manganese steel casting process is fully equipped with facilities, featuring 8 heat treatment units.

Inspect all the rough casting dimensions using equipment.